北京鑄鐵平板銷售15931713663

時(shí)間:2016/1/2 9:08:56

瀏覽量:420

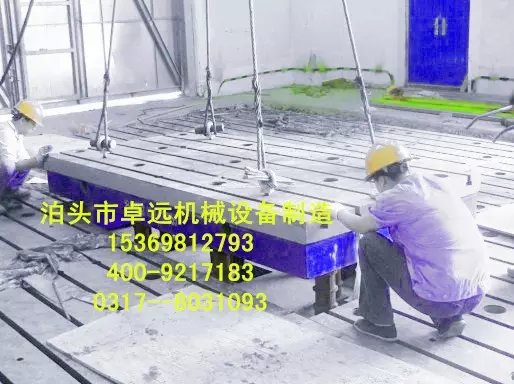

專業(yè)銷售北京鑄鐵平臺(tái)

公司名稱:泊頭市卓遠(yuǎn)機(jī)械設(shè)備制造有限公司

注冊(cè)地址:河北省泊頭市交河開發(fā)區(qū)

傳真號(hào)碼:0317-8031093

聯(lián)系方式:(河北)15369812793 褚連勝

15931713663 褚連勝

鑄鐵平板是用于精密零件的測(cè)量和檢驗(yàn)!平臺(tái)的表面技術(shù)要求�����。

1�、工作表面不應(yīng)有銹跡、劃痕�、碰傷及其他影響使用的外觀缺陷。

2�、工作表面不應(yīng)有砂孔、氣孔�����、裂紋�����、夾渣及縮松等鑄造缺陷��。各種鑄造表面應(yīng)清除型砂���、且表面平整���,涂漆牢固。各棱邊應(yīng)修鈍����。在精度等級(jí)低于“00”級(jí)的平板工作面上,對(duì)于直徑小于15mm的砂孔允許用相同的材料堵塞����,其硬度應(yīng)低于周圍材料的硬度。在工作面上堵塞的部位應(yīng)不多于四處��,其相互之間的距離應(yīng)不小于80mm��。

3�����、相對(duì)兩個(gè)側(cè)面上��,應(yīng)設(shè)置有安裝手柄、吊環(huán)等吊裝設(shè)施的螺紋孔或圓柱孔�。設(shè)計(jì)吊裝位置時(shí)應(yīng)考慮盡量減少因吊裝而引起的變動(dòng)。

4����、根據(jù)用戶要求,在板工作面上設(shè)置螺紋孔或溝槽后�,這些部位不應(yīng)出現(xiàn)高于工作面的凸起現(xiàn)象。

5��、應(yīng)采用優(yōu)質(zhì)細(xì)顆料的灰口鑄鐵或合金鑄鐵制造��。

6��、工作面的硬度應(yīng)為HB 170-220���。

7���、工作面應(yīng)采用刮削工藝,對(duì)于“3”級(jí)平板工作面也可以采用刨削工藝�,刨削工作表面的表面粗糙度按輪廓算術(shù)平均偏差Ra值應(yīng)不大于5um

8、應(yīng)經(jīng)過穩(wěn)定性處理和去磁���。

平 面 度:可分實(shí)驗(yàn)室級(jí)(Reference)���、校驗(yàn)級(jí)(Master)、工 具室級(jí)(Working) 三級(jí)

平面研磨:平臺(tái)在很早的時(shí)候,人們利用三塊平臺(tái)相互匹配以產(chǎn)生真平平面�。一個(gè)熟練而 又有耐心的 磨石師傅可以不藉助任何量測(cè)儀器,而僅利用三平臺(tái)相互匹配的 方式,做多次90度之旋轉(zhuǎn), 即可產(chǎn)生令人難以相信的真平程度。

平面度:

1.AA級(jí):其平面度(μm)= 1+1.6D2 (D為平臺(tái)對(duì)角線長或直徑),用於高度精密 之測(cè)定之用, 常用於實(shí)驗(yàn)室����。

2. A級(jí):其平面度為AA級(jí)之兩倍誤差,常用於工具檢驗(yàn)室作精密量具之檢驗(yàn)之用。

3. B級(jí):其平面度為AA級(jí)之四倍誤差,常用於工具檢驗(yàn)室或在現(xiàn)場(chǎng)檢驗(yàn)量具或劃線之用����。

Cast iron plates are used for the measurement and inspection of precision parts! Surface technical requirements for the platform.

1. The working surface should be free of rust, scratches, bumps and other appearance defects that affect the use.

2. There should be no casting defects such as sand holes, pores, cracks, slag inclusions and shrinkage on the working surface. All kinds of casting surfaces should be cleaned of sand, and the surface is flat and the paint is firm. Each edge should be blunt. For flat work surfaces with a precision class lower than “00”, sand holes with a diameter of less than 15 mm are allowed to be blocked with the same material and their hardness should be lower than the hardness of the surrounding material. There should be no more than four places on the working surface, and the distance between them should be no less than 80mm.

3. On the opposite sides, threaded holes or cylindrical holes for lifting equipment such as handles and lifting rings should be provided. When designing the hoisting position, consideration should be given to minimizing changes due to hoisting.

4. According to the user's requirements, after the threaded holes or grooves are set on the working surface of the board, these parts should not appear convex above the working surface.

5. It should be made of gray cast iron or alloy cast iron with high quality fine particles.

6. The hardness of the working surface should be HB 170-220.

7. The working surface should adopt the scraping process. For the “3” grade flat working surface, the planing process can also be adopted. The surface roughness of the planing work surface should be no more than 5um according to the arithmetic mean deviation of the contour.

8, should be subjected to stability processing and demagnetization.

Flat degree: can be divided into laboratory level (Reference), verification level (Master), tool level (Working) level

Planar Grinding: At very early stages, people used three platforms to match each other to create a true flat plane. A skilled and patient grindstone master can create an unbelievable level of flatness without the use of any measuring instrument, but by using three platforms to match each other and doing multiple 90-degree rotations.

Flatness:

1.AA grade: its flatness (μm) = 1+1.6D2 (D is the diagonal length or diameter of the platform), used for highly accurate measurements, often used in the laboratory.

2. Class A: The flatness is twice the error of AA grade, which is often used in the inspection of precision measuring tools in the tool inspection room.

3. Class B: The flatness is four times the error of AA level, which is often used in tool inspection room or in the field to test gage or scribing.

Company name: botou zhuoyuan mechanical equipment manufacturing co.,LTD

Registered

address: jiaohe development zone, botou city, hebei province

Fax

number: 0317-8031093

Contact

information: 15369812793 (WeChat with the same number) liansheng chu

Postcode:

062151

Enterprise

email:1358827475@qq.com

Account

Opening Bank: Botou Branch of Bank of China

Account

number: 100399943203

Agricultural

bank account number: 6228481739059615270

http://zhuoyuanjixie.com